Turning ideas into impact: UKZN students solve real-world problems

Engineering

Muhammed Yusuf Ismail (left) and Ruchir Somaru built a wheelchair that can navigate rough terrain and be converted into a stretcher in emergencies.

Image: Leon Lestrade/Independent Newspapers

Ahmed Jeewa working on a remote-controlled lifebuoy that will make it safer for responders who assist people in distress in the ocean.

Image: Leon Lestrade/Independent Newspapers

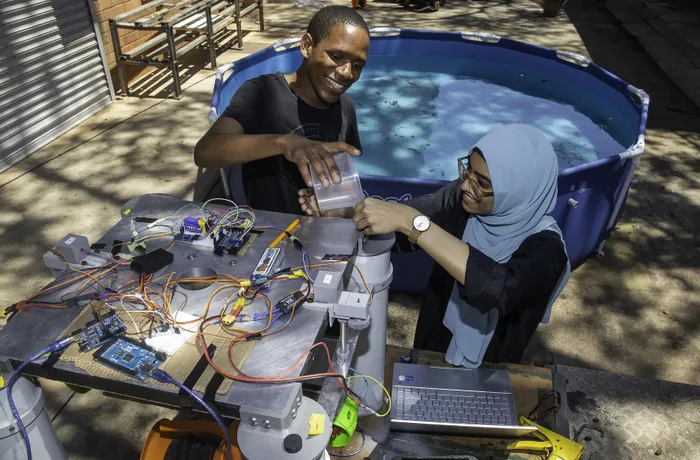

Andile Innocent Mncwabe and Azraa Mahomed Khan working on their floating rocket launch platform.

Image: Leon Lestrade/Independent Newspapers

Prenavan Nayagar controls the Axis Prismatic–Spherical–Spherical Delta Robot, while his teammates Lusanda Siphephelo Phakathi, and Durand Moonsamy monitor it from the other side.

Image: Leon Lestrade/ Independent Newspapers

UKZN’s final-year mechanical engineering students showcased their projects at an open day yesterday, demonstrating how years of hard work can be turned into innovations that improve lives.

While some of the projects were a bit obscure and difficult to grasp, many others were practical and could be put to use almost immediately.

The exhibits included a vacuum tumbler for meat processing and a system that transforms faecal sludge into valuable biomass through an innovative deep-frying process using waste cooking oil. “Essentially they deep fried sh*t,” one attendee laughingly told the Independent on Saturday.

A team led by Ruchir Somaru and Muhammed Yusuf Ismail built a wheelchair that can navigate rough terrain and be converted into a stretcher in emergencies.

The wheelchair is powered by two 500W hub motors connected to 26-inch drive wheels, supported by front pneumatic wheels for stability. The occupant can steer, accelerate, and brake using an electrically controlled joystick.

“In rural areas, when they respond to patients, it's quite difficult to transport someone using the current stretcher that's available,” said Somaru. “With this design and the combined suspension system, ambulance services can transport patients much more easily. There’s also better stability compared to existing stretchers on the market.”

Ismail added that the wheelchair could serve multiple purposes. “A disabled person can use it as a normal wheelchair, but it can also recline for leisure. If they need to reach countertops, they can raise it to be at eye level with others. And in emergencies, it can help paramedics easily transport injured people—whether they need a wheelchair or a stretcher.”

Another team, led by Ahmed Jeewa, developed a search-and-rescue sea vessel aimed at improving emergency responses in maritime operations.

They created a remote-controlled lifebuoy that’s safer and more efficient than traditional rescue methods. Jeewa explained that the device consists of two fibreglass halves fitted and bolted together, with the mold produced using 3D printing. “We ride it out using the remote control. It goes to the person in the water, they hold onto the handles, and they’re brought back remotely as well,” he said. The device can be controlled from the shore for up to 100 metres.

A team consisting of Uzair Haffejee, Andile Innocent Mncwabe, and Azraa Mahomed Khan designed and built a floating rocket launch platform for the Aerospace Systems Research Institute’s (ASRI) commercial launch vehicle.

Resembling a mini oil rig, the platform integrates three subsystems: a buoyant deck and pontoon structure, an electric propulsion system for navigation, and a mechanically actuated strongback for rocket elevation and support.

Khan said it was designed for remote operation as a safety measure to reduce onboard human involvement. “It’s a floating rocket launch platform to promote ocean-based launches,” she said. “We’re testing the feasibility of a scale model to assess its hydrodynamic performance in water. Once validated, it can be scaled up to a full-size version.”

One of the most intricate projects on display was the 6-Axis Prismatic–Spherical–Spherical Delta Robot, a novel parallel manipulator developed by Prenavan Nayagar, Lusanda Siphephelo Phakathi and Durand Moonsamy.

Nayagar said their design was a precision-based robot aimed at boosting South Africa’s presence in the global robotics sector, currently dominated by Chinese and Japanese markets. “It’s connected by six linear ball-screw actuators. These actuators amplify the load the robot can lift—an improvement over conventional delta robots, which have only three degrees of freedom and are belt-driven,” he explained.

He said their prototype was eight times stronger than competitors of similar size. “It’s also designed to improve accuracy, as parallel robots tend to concentrate errors toward the centre of gravity. Each limb compensates for errors in the others, making it ideal for precision tasks like additive and subtractive manufacturing,” Nayagar said.